PROJECT: INSTALLATION OF COINCINERATION (GASIFICATION PLANT + COMBUSTION) OF CATEGORY 1 MEAT AND BONE MEAL, FOR THE USE OF SYNGAS IN CURRENT THERMOXIDORS

PUBLIC GRANT

This Project, with file number C-20-PDR-18, has been subsidized by announcement investments in transformation and commercialization of agricultural products for the period 2014-2020, co-financed by the European Agricultural Fund for Rural Development (EAFRD).

|  |  |

PUBLIC AID: 30% (€ 696,951.39)

OBJECT OF THE PROJECT

Use of a category 1 by-product through the co-incineration of category 1 meat meals, with the sole objective of using the meals for energy as fuel, obtained in the process, to introduce, in the current THERMOXIDORS, the syngas obtained by meals gasification, through which the heat is used in the recovery boilers installed to generate the steam required by the current category 1 and 2 transformation plants.

This facility is expected to drop 6,000 tons of CO2 per year.

PROJECT DESCRIPTION

There are four phases:

1. The first phase that stands out is the drying phase, by means of which part of the moisture in the fuel is evacuated to reach the ignition temperature.

2. The second phase is pyrolysis, an endothermic thermochemical process by which fuel decomposes into a series of compounds depending on the reactor temperature and oxygen concentrations. In this phase three products are obtained, a gas, a liquid and a solid residue, the latter being assimilable to charcoal.

In these circumstances, the gases obtained are mainly composed of CO, CO2, H2 and CH4 and other longer chain hydrocarbons, a mixture known as synthesis gas (or Syngas).

3. In updraft reactors, the third stage is reduction, where the carbonaceous residue reacts with the water steam produced in the first stage, with carbon dioxide and hydrogen, and the gases react with each other to produce the mixture of final gas.

4. The fourth stage is the oxidation of the heavier fraction (carbonaceous) of the fuel when it comes into contact with the gasifying agent (air, oxygen, or water steam). In this stage, a series of fundamentally exothermic oxidation reactions take place, through which the necessary heat is generated for the process to be maintained.

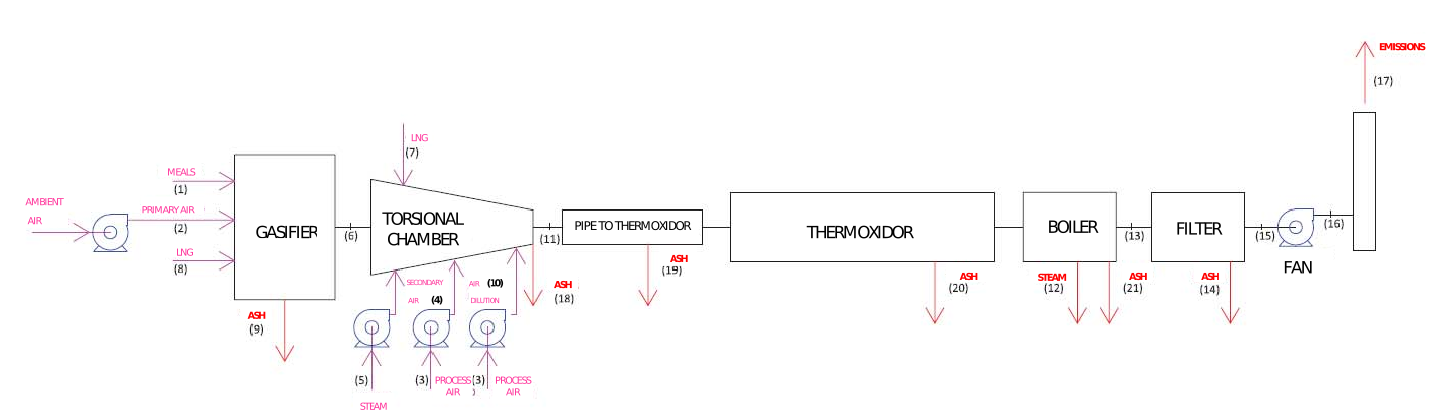

The gasification plant has a UPDRAFT type gasifier. In an updraft gasifier type, the meat meals are fed through the upper part of the gasifier, while the air come through the lower part. The gas produced flows upwards, in the opposite direction to the fuel, come out the upper part of the gasifier.

In this type of gasifiers, there is a clear differentiation of each of the phases of the process, indicated above.

The resulting gas comes out at a low temperature from the top of the gasifier. The ash is dropped, with the solids, in the opposite direction to the gas flow and is removed by the lower part of the gasifier.

With this new operation through the gasification and combustion system in the torsional chamber, the hot gases (850ºC) due to combustion are sent, indistinctly, to Thermoxidor 1 or Thermoxidor 2, already existing in the current facilities, taking advantage of the heat in the adjacent boilers.

The exhaust gases are directed towards the purification system before being expelled to the atmosphere.

Category 1 meat meals will be transported from the plant’s current storage hopper to a dosing bin located in the upper part of the gasifier. The transport of the meat meals will be carried out by chain conveyors (redler).

The gasifier will allow the treatment of a maximum flow of 1,945kg / h of type 1 meat meals, with a total of 8,200Tn per year.

The syngas produced in the gasifier will be directed through the top of the gasifier, up to the torsional chamber.

The torsional chamber is a combustion chamber composed of a metal seal and a cylindrical refractory body. It has three air fans: one for supplying primary combustion air; another for the supply of secondary air and a third for the dilution air, which will allow the control of the temperature of the combustion gases that will go to the thermoxidors, so that it remains within the ranges required for their operation. (> 850 ° C).

The gas treatment system has a bag filter for the elimination of solid particles and a reactor in which sodium bicarbonate and activated carbon are injected to eliminate acid gases, dioxins and furans, before to be sent to the atmosphere.

PROCESS FLOW CHART